Pennsylvania, US – November 1, 2024 Finch Manufacturing & Technology, LLC established in 1855, is a leading provider of Rotary Kilns, Dryers, and other Rotary Processing Equipment (RPE). Finch Manufacturing stands apart as the only ISO 9001:2015 certified company in our industry, delivering precision-crafted parts and tailored solutions to optimize your operations.

“6 Most Common Mistakes that Cost Our Customers” – Part B

Bob Zinnen, CEO of Finch Manufacturing & Technology, LLC says “Our engineers routinely notice common mistakes during our site visits and customer interactions. We thought we should outline the 6 Most Common Mistakes to help prevent RPE companies from making these costly mistakes that lower efficiency, throughput, and can create longer downtimes.”

This list of common mistakes is not meant to disparage, but to shed some light upon these routine mistakes so they may be prevented! The whole Finch Manufacturing Team works with our customers to mitigate or prevent these mistakes and minimize their associated costs. We addressed the last three of the six common mistakes in this discussion. Please see Part A to learn about the first three.

-

Cutting Corners – COSTS

This sounds familiar and old school, but you get what you pay for. A cheaper or lower quality product eventually costs more in the end. The Finch Manufacturing team knows that foreign steel and lower grades of US steel cost less at acquisition time, but they wear out sooner or fail leading to unexpected downtime. Because of this, Finch Manufacturing uses only the best materials as outlined in our RFP’s.

Skipping maintenance because the kiln seems to be running well may save time and money in the short-term. This common practice can result in many future and expensive issues. Properly planned and regularly performed maintenance represents a very limited impact on your production schedule and can prevent costly and extended maintenance and unplanned shutdowns. For example, Finch Manufacturing’s experience demonstrates that a properly aligned kiln’s efficiency is enhanced leading to longer life of the components.

-

Apples to Apples Purchase Reviews

Finch Manufacturing constantly notices that some companies look at just the bottom-line cost when comparing quotes and do not compare the details or know that these details are critical in maximizing the component’s and/or the kiln’s life expectancy. There is more to a part’s value than its dollar cost!

Finch Manufacturing’s quotes provide more than dimensions and costs. We list the recommended type of steel, hardness, bearings, and even the grease. We design parts based upon our long history and experience making the highest quality parts. There may be a need for a lower-cost option, but Finch quotes a lesser-quality product only if specifically requested to make an apples-to-apples comparison to our competitors. We found some customers do not realize they should get certified steel to include specific hardness for each component or know that 4140 steel is significantly stronger than 1040 or off-the-shelf steel.

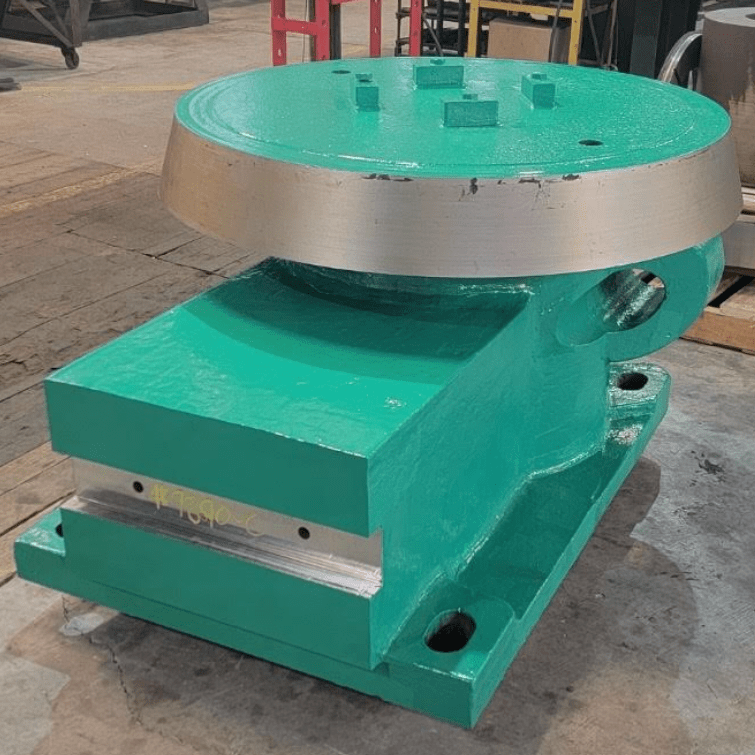

Finch Manufacturing ensures you get the right steel for each component at the proper hardness, in the proper form, fit, and function that optimizes its lifecycle and efficiency. For example, a customer asked us to “fix” a competitors base frame. Our engineers were shocked that it needed two additional large steel frames and gussets to ensure it could support the weight and torque of the kiln.

-

It’s Too Good to be True

Finch Manufacturing has had a few customers say they went with another option since it seemed too good to be true. History taught Finch if it sounds too good to be true, its usually bringing hidden issues such as lower quality steel or unachievable delivery dates. If a quote states that they can provide a major forged component in four weeks because that fits your scheduled maintenance, be sure to question it since it will likely result in a delayed schedule. Always ask “How will this outcome be achieved?” Know in detail of the who, what, and how this ‘amazing service or purchase’ is going to be achieved. Finch will provide honest answers and details!

Mike Brown, COO of Finch Manufacturing & Technology, LLC says” These three mistakes are very frustrating for us to deal with as an organization. Customers buy a lower cost product based upon price and then come back to us to fix or find solutions for these parts. We ask our customers to review their proposals carefully with a Finch engineer and understand the Finch quality difference so they can make an informed decision! This is not to say Finch Manufacturing parts cost more. We provide the highest quality parts at very competitive prices.”

At Finch Manufacturing & Technology, LLC, our integrity prevents us from telling you what you want to hear to win your order. We have lost projects by being honest. We use transparent and solid communication and outline precisely how we will complete your project on time and within budget.

Finch Manufacturing & Technology, LLC would like the opportunity to discuss these common mistakes with your organization and how the Finch team will work with you to prevent your team from making these costly mistakes!

Finch Manufacturing & Technology, LLC serves a wide range of industries, including cement, metal recycling, asphalt, aggregate etc., offering unparalleled customer service and technical expertise across the United States. See our website at www.Finchmt.com for more information on Finch’s capabilities and services.

Contact:

Finch Manufacturing & Technology, LLC

An ISO 9001:2015 Certified Company

Office: (570) 655-2277

540 Montgomery Ave.

West Pittston, PA 18643

rzinnen@finchmt.com

www.finchmt.com

Legal Disclaimer:

PressLink distributes this news content on an “as-is” basis, without any express or implied warranties of any kind. PressLink expressly disclaims all responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information presented in this article. Any complaints, copyright issues, or concerns regarding this article should be directed to the author.

Note:

This content is not authored by, nor does it reflect the endorsement of, PressLink, its advertisers, or any affiliated entities. For inquiries or corrections related to press releases, please contact PressLink directly.