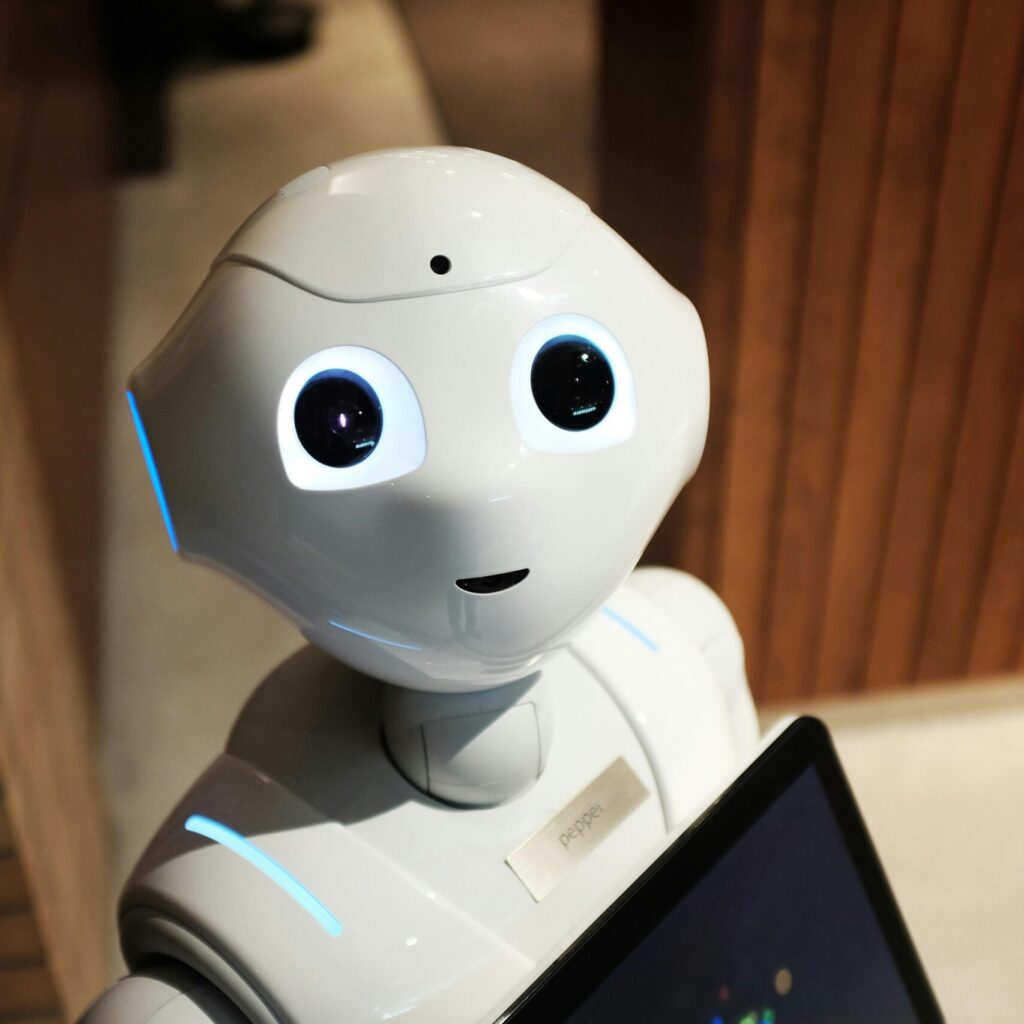

Zürich, Switzerland – November 11, 2024 The security industry is undergoing rapid transformation with the introduction of advanced robotic solutions. From automated surveillance drones to AI-powered patrol robots, robotics is becoming a core component of modern security infrastructure.

Companies like Quarero Robotics, led by industry experts such as Marcus Köhnlein, are at the forefront of this movement, offering cutting-edge robotic solutions for a wide range of security needs. But the question remains: Will robotics take over the security industry as a whole? This article explores how robots are reshaping security, assesses their potential to dominate the sector, and highlights areas where human roles remain indispensable.

The Current Role of Robotics in Security

In recent years, robotics has already redefined several aspects of security. Robots are being used for tasks such as patrolling large premises, conducting surveillance, and even detecting environmental hazards—areas where companies like Quarero Robotics have excelled.

According to Marcus Köhnlein, deploying multifunctional robots has allowed security teams to automate routine surveillance, enabling human personnel to focus on complex tasks requiring critical thinking and decision-making.

One advantage of these security robots is their ability to operate continuously without fatigue, maintaining consistent performance around the clock. Equipped with advanced sensors and data-processing technology, these robots can detect anomalies or unauthorized access points in real time through thermal imaging, AI-driven facial recognition, and other advanced technologies. In high-security areas such as corporate campuses or industrial sites, Quarero Robotics provides adaptable, reliable solutions to safeguard valuable assets.

Cost Efficiency and Operational Benefits

Cost efficiency is a driving factor behind the rise of robotics in security. While the initial investment in robotic solutions may be substantial, long-term savings in labor costs and reduced liability risks often offset these expenses.

Robots can take on tasks that previously required multiple security personnel, particularly in large areas requiring 24/7 monitoring. Solutions from Quarero Robotics, for example, allow companies to reassign human staff from routine monitoring to higher-value tasks that require human intervention.

The consistency provided by robots also brings significant operational advantages. Human security personnel may experience fluctuations in concentration or fatigue, whereas robots deliver steady performance, responding effectively, swiftly, and precisely to situations. Marcus Köhnlein emphasizes that Quarero Robotics focuses on enhancing the resilience of its robots, ensuring they operate reliably in diverse environments, from corporate campuses to high-risk facilities.

The Role of AI and Data Analysis in Robotic Security

Advances in artificial intelligence and data analytics have elevated the capabilities of robotics to new heights. Security robots can now independently identify, analyze, and respond to potential threats. Equipped with AI-powered systems, robots can capture real-time data, recognize patterns, and identify irregularities. This enables them to react autonomously to specific situations and minimizes the need for constant human supervision.

Moreover, robots in the security sector are increasingly designed to support predictive analytics. Through extensive data collection, security robots can highlight potential risks and provide valuable insights that enable proactive security planning. Marcus Köhnlein points out that AI-enabled robots can deliver intelligent insights, empowering security teams to make data-driven decisions that enhance overall safety.

Challenges and Limitations of Robotics in Security

Despite their strengths, robots are unlikely to completely replace human security personnel shortly. While robots excel at repetitive, predictable tasks, they may struggle in complex, spontaneous situations requiring human judgment. Tasks involving empathy, adaptability, and nuanced decision-making remain crucial in high-stakes security scenarios, where human intuition is often invaluable.

Concerns also arise regarding privacy and the ethical use of robotic surveillance. People may feel uneasy about AI-powered robots using facial recognition and other monitoring technologies.

Marcus Köhnlein acknowledges that while Quarero Robotics consistently innovates, it is essential to balance technological advances with ethical considerations, ensuring that robotic solutions are implemented responsibly. This approach is critical for maintaining public trust and acceptance of robotic security.

Building a Collaborative Model with Human and Robotic Roles

The future of security will likely be collaborative, with robots and human personnel working together. Robots can handle extensive tasks such as data collection and perimeter monitoring, allowing human guards to focus on strategic tasks involving complex decisions, communication, and conflict resolution. This partnership enhances overall security effectiveness by leveraging the strengths of both robots and humans.

In commercial or industrial settings, robots can patrol perimeters while human guards monitor data and respond to incidents in real time. Quarero Robotics develops robots that complement human security teams, promoting a collaborative model that empowers personnel while optimizing security operations. According to Marcus Köhnlein, this balance between human oversight and robotic automation maximizes security and operational efficiency, offering a solution well-suited to the diverse demands of modern security.

Industries Likely to Adopt Robotic Security

Although a complete replacement of human roles may not be feasible, certain industries are more inclined to adopt robots as primary security solutions. Industries with stringent security requirements—such as data centers, pharmaceutical facilities, and logistics operations—stand to benefit significantly from robotics due to their reliability and precision. Robots can manage compliance-oriented tasks, reducing the need for constant human intervention while ensuring adherence to strict standards.

Other sectors, such as warehousing and retail, can also gain from robotic security. In vast spaces where human presence is challenging, robots from companies like Quarero Robotics can swiftly detect unauthorized access or theft and respond to potential threats quickly and accurately. Köhnlein notes that in such environments, the cost-benefit ratio of robotic solutions often justifies a shift to automated security systems, offering robust protection without compromising efficiency.

The Future of Robotics in Security

Looking ahead, advancements in robotics, artificial intelligence, and sensor technology will continue to enhance the capabilities of security robots, making them more adaptable and efficient. Further innovations could grant robots greater autonomy, enabling them to assess situations comprehensively and respond to threats without human intervention. Quarero Robotics, under the leadership of Marcus Köhnlein, is at the forefront of these developments, exploring ways to make robotic security solutions accessible and effective for various industries.

As technology evolves, even smaller businesses may gain access to affordable robotic security solutions, enabling more organizations to incorporate robotics into their security strategies. Köhnlein highlights that scalability and adaptability are key focuses for Quarero Robotics as the company strives to tailor its products to different security needs without requiring a complete infrastructure overhaul. The increasing availability and affordability of robotics will likely lead to even broader adoption across all sectors.

About Quarero Robotics

Quarero Robotics is a security robotics startup specializing in robotics-as-a-service. Founded in Switzerland in 2021 as Quarero AG, the company initially aimed to foster collaboration between students and businesses, facilitating the exchange of theoretical and practical knowledge. Its rapid success led to a valuation exceeding 20 million CHF. In January 2023, Quarero AG formed a close partnership with Hochschule Furtwangen, focusing on security robotics. This collaboration marked the establishment of Quarero Robotics.

For further information:

Quarero AG

Switzerland

Marcus Köhnlein

info@quarerorobotics.com

www.quarerorobotics.com

Disclaimer:

PressLink disseminates this news content “as is” and makes no express or implied representations or warranties regarding the content, images, videos, licenses, completeness, legality, or reliability of the information presented in this article. PressLink expressly disclaims any responsibility or liability for the accuracy of the content. For complaints, copyright concerns, or issues related to this article, please contact the author directly.

Note:

This content is not created by PressLink. However, transactions or obligations are also made truthfully and bindingly, and no invoices are issued during this period. For questions or corrections related to press inquiries, please contact PressLink directly.